World Class Manufacturing Methodology as an Example of Problems Solution in Quality Management System

Por um escritor misterioso

Descrição

The article presents the methodology of World Class Manufacturing (WCM) used in one of the factory the mechanical engineering industry. The company has factories all over the world, while in Poland produces on average 800 ready-made machines by a year. The article presents the following pillars WCM: S (Safety) CD (Cost Deployment), Fl (Focused Improvement), AA (Autonomous Activity), PM (Professional Maintenance), QC (Quality Control), L & CS (Logistics & Customer Service), EEM (Early Equipment Management), EPM (Early Product Management), PD (People Development), E (Environment). Each pillar uses methods and tools. By using the methodology of WCM in the factory has reduced losses and improved the quality of the products.

%20Improvement%20System.png?width=2134&name=The%20Total%20Quality%20Management%20(TQM)%20Improvement%20System.png)

The Total Quality Management (TQM) Improvement System

Lean Production and World Class Manufacturing: A Comparative Study

What is World Class Manufacturing (WCM)? - TheLeanSuite

8 Total Quality Management Principles

What is Master Data Management Definition, Tools, Solutions

World Class Manufacturing or WCM, What Is It ?

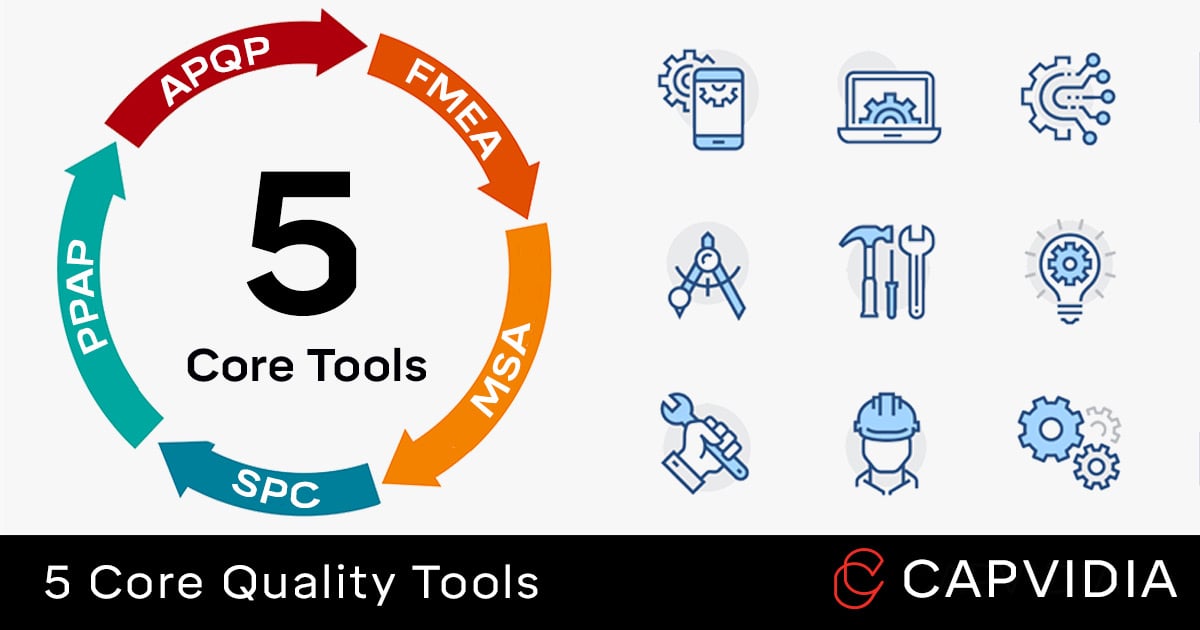

5 Core Quality Tools

The Ultimate Guide to Implementing a Quality Management System In

Continuous Improvement (A Kaizen Model)

Model of process-based quality management system [3].

World Class Manufacturing – Makigami Info

de

por adulto (o preço varia de acordo com o tamanho do grupo)